Reverse Engineering

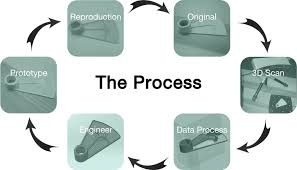

HB-SET provides support in the Reverse Engineering to evaluate the product for replication, for Design of New part, Copy of an existing part and Recovery of damaged part or broken part.

From Portable CMM and Laser Scanning Measurement Services to complete Reverse Engineering projects.

We can provide you with:

• Calculate geometric, dimensions and tolerances (GD and T) measurements and compare complex geometry, surfaces, and feature positions to nominal data and verify the object’s conformance to the specifications

• Compare part measurements of an object to the CAD model to determine real-time deviations from the design, saving precious time and significant cost to our customer

• Perform 3D Reverse Engineering by Digitizing a part or object to create its fully surfaced 3d model prototype.

Focus Areas |

|

1.Scan-to-CAD

2.Optimization:

capturing the data of a current piece of equipment and improve its performance.

3.Data Capture:

Learning about a competitor’s latest research by capturing data to secure as much information as possible to understand its capabilities. It may result in development of similar product.

4.Documentation improvement:

for a piece of equipment, production, operation or maintenance have shortcomings and the original designers are not available.

5.Legacy Equipment:

capture the data of a piece of equipment or product that was design pre digitization.

6.Planned Preventative Maintenance (PPM)

program when we capture the data and have this archived. The data will then be available to manufacture spares, therefore reducing the ‘downtime’ and saving time and money in a manufacturing process.

7.Reproducing a digital model in CAD

8.Reduction in quicker upgrades / versions of products